Introduction

The safety and performance of a vehicle heavily depend on its braking system. Among the crucial components are brake pad weights, which enhance the functionality of aftermarket automotive brake parts. This essay explores the significance of brake pad weights and brake hardware, particularly focusing on the front brake pad set with two counterweights. Notably, OLYM Metal has developed more than 60 kinds of brake pad weights since 2016, offering superior quality and competitive prices while exporting to Europe, the USA, and other regions. Additionally, OLYM Metal can provide OEM standard steel casting hardware for automobiles, ensuring that manufacturers have access to reliable and high-quality components.

The Importance of Brake Pad Weights

Brake pad weights are designed to mitigate vibrations and enhance stability during braking. They serve several essential functions:

Vibration Dampening

When a vehicle comes to a stop, various forces act on the brake pads. These forces can cause vibrations that lead to noise and reduced braking efficiency. Brake pad weights help absorb and dampen these vibrations, ensuring a smoother and quieter braking experience.

Improved Contact with Rotors

Proper weight distribution ensures that brake pads maintain optimal contact with the rotors. This consistent contact is crucial for efficient braking and helps prevent uneven wear on both the pads and rotors.

Enhanced Safety

By reducing noise and ensuring consistent braking performance, brake pad weights contribute to overall vehicle safety. They are particularly important in high-performance vehicles where braking precision is critical.

Aftermarket Automotive Brake Parts: A Growing Market

The aftermarket automotive brake parts market has expanded significantly in recent years, providing vehicle owners with a variety of options for upgrading or replacing their braking components. Key aspects include:

Diverse Product Range

The aftermarket offers a wide range of brake parts, including pads, rotors, calipers, and brake hardware. This diversity allows consumers to customize their vehicles according to their specific needs and driving styles.

Cost-Effectiveness

Aftermarket parts are often more affordable than original equipment manufacturer (OEM) components, making them a popular choice for budget-conscious consumers. This cost-effectiveness does not necessarily mean compromising quality; many aftermarket parts are manufactured to meet or exceed OEM standards.

Performance Enhancements

Many aftermarket brake parts are designed to improve performance. For instance, high-performance brake pads can offer better stopping power, while upgraded rotors can dissipate heat more effectively, reducing brake fade.

Brake Hardware: The Backbone of the Braking System

Brake hardware is an essential component of the braking system, ensuring that all parts work together efficiently. Key elements include:

Mounting Brackets

These brackets secure the calipers and pads in place, providing stability and alignment. Proper installation of mounting brackets is crucial for optimal brake performance.

Bolts and Fasteners

High-quality bolts and fasteners are critical for the integrity of the brake assembly. Using subpar hardware can lead to catastrophic failures and compromised safety.

Brake Pad Shims

Brake pad shims, often used in conjunction with weights, help reduce noise and improve alignment. They are an essential part of ensuring smooth operation and preventing metal-to-metal contact.

Counterweights in Brake Pad Sets

The front brake pad set with two counterweights exemplifies effective brake hardware design. By balancing the braking forces, this setup enhances stability and reduces vibrations, leading to improved braking performance.

OLYM Metal: A Leader in Brake Pad Weights and Hardware

Since its inception, OLYM Metal has established itself as a leader in the production of brake pad weights and hardware. Their commitment to quality and innovation has led to the development of over 60 kinds of brake pad weights since 2016.

Quality Assurance

OLYM Metal prioritizes quality throughout its manufacturing processes. Each brake pad weight is produced under strict quality control standards, ensuring reliability and performance under various driving conditions.

Competitive Pricing

By streamlining their production processes, OLYM Metal offers competitive prices without sacrificing quality. This affordability allows them to cater to a wide range of customers, from individual vehicle owners to large automotive manufacturers.

Global Reach

OLYM Metal exports its products to various regions, including Europe and the USA. This global presence underscores their reputation as a trusted supplier of high-quality automotive parts.

OEM Standard Steel Casting Hardware

OLYM Metal can provide OEM standard steel casting hardware for automobiles. This capability ensures that manufacturers have access to reliable components that meet stringent industry standards, further enhancing vehicle safety and performance.

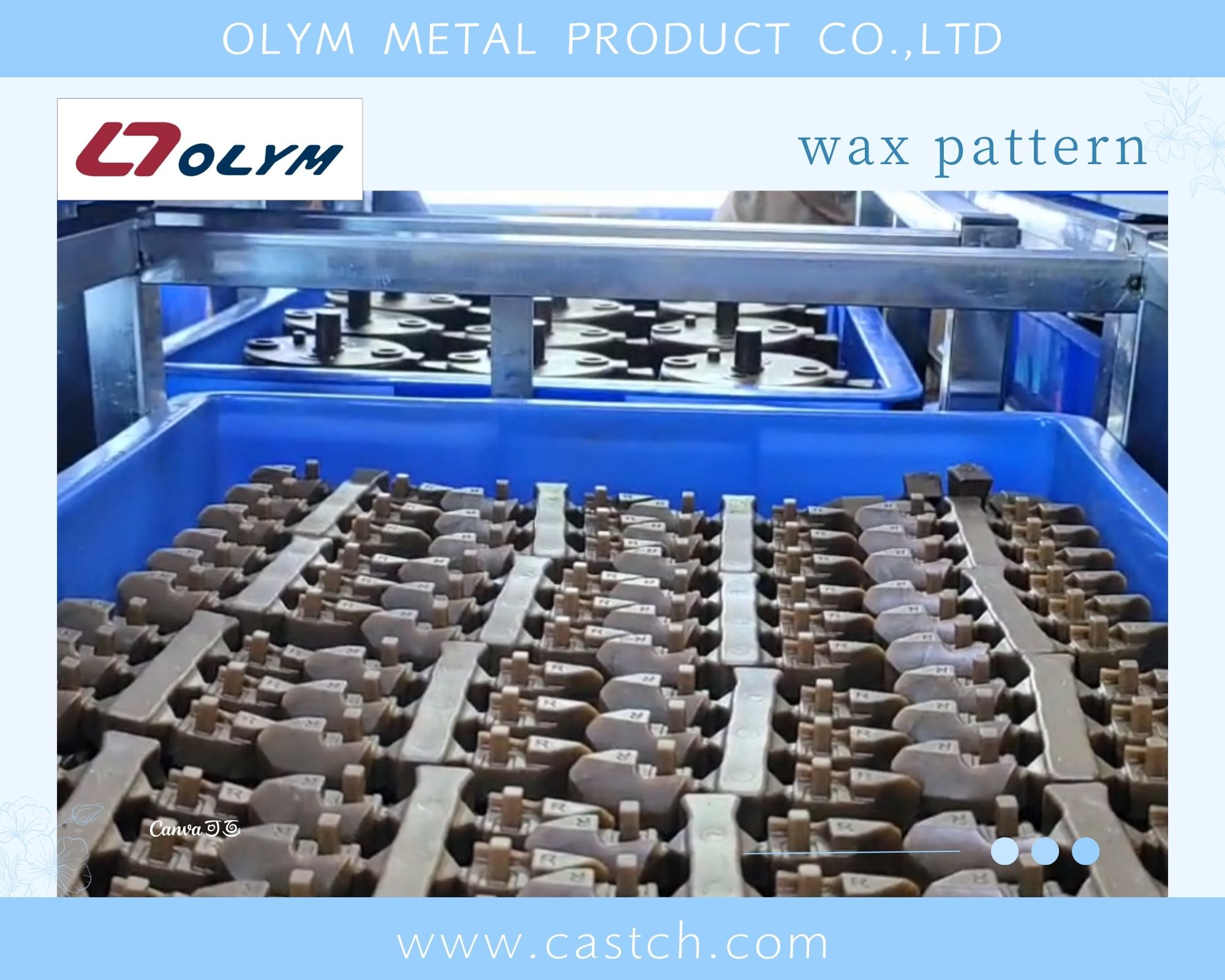

The Manufacturing Process of Brake Pad Weights

Understanding the manufacturing process of brake pad weights and hardware is essential for appreciating their quality and reliability.

Material Selection

The choice of materials is critical in producing effective brake pad weights. High-strength alloys or steel are commonly used to ensure durability and resistance to wear, providing long-lasting performance.

Precision Engineering

Advanced manufacturing techniques, including computer-aided design (CAD) and computer numerical control (CNC) machining, are employed to ensure that each weight and shim is precisely engineered to fit specific vehicle models. This precision is crucial for ensuring optimal performance.

Quality Control Measures

Rigorous quality control measures are implemented throughout the production process. This includes testing for durability, performance, and compatibility with various brake systems. Ensuring that each part meets stringent standards is vital for consumer safety.

The Impact of Brake Pad Weights on Vehicle Performance

The integration of brake pad weights in automotive design has led to significant improvements in vehicle performance. Key impacts include:

Enhanced Braking Efficiency

The consistent contact between brake pads and rotors facilitated by weights leads to improved braking efficiency. Vehicles equipped with high-quality brake pad weights can achieve shorter stopping distances, crucial for safety.

Reduction in Brake Fade

Brake fade occurs when the braking system overheats, leading to reduced effectiveness. The use of brake pad weights can help dissipate heat more effectively, thereby minimizing the risk of brake fade during extended use.

Improved Driver Experience

A smoother, quieter braking experience contributes to overall driver satisfaction. The reduction of noise and vibrations makes for a more comfortable ride, enhancing the appeal of vehicles equipped with high-quality brake components.

Conclusion

Brake pad weights and shims play an integral role in the performance and safety of the braking system. As a key component of aftermarket automotive brake parts, they enhance stability, reduce noise, and improve braking efficiency. OLYM Metal’s dedication to developing superior-quality brake pad weights and hardware, along with their ability to provide OEM standard steel casting hardware for automobiles, positions them as a leader in the industry. As automotive technology continues to evolve, the importance of high-quality brake components remains paramount in ensuring safe and reliable driving experiences. With a growing emphasis on performance and safety, the future of brake pad weights and aftermarket automotive brake parts looks promising, paving the way for innovations that will further enhance vehicle safety and driver satisfaction.