a valve for controlling the flow of pressurized fluid having a valve body including a plurality of fluid entrance and emission ports opening into a confined cavity. a valve spool is held captive in the cavity and is movable therein to control the flow of fluid selectively through the ports and the cavity. at least one of the valve members is constructed of resilient material. such use of resilient material not only results in a unique valve structure but also permits production thereof by a unique method wherein either the valve body or the valve spool is deformed for the assembly of parts.

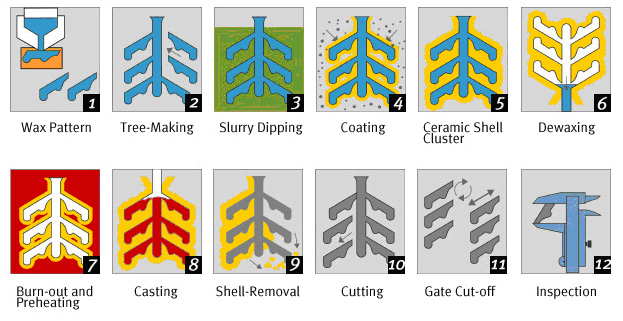

picture show the investment casting method of manufacturing the valve of the present invention.

such a unitary structure insures separation of the controlling pressurized fluid from the controlled pressurized fluid. the valve may be constructed by the lost wax or investment casting process.

valve castingmay be manufactured by the investment casting or lost wax" process. while such process may be used to manufacture any of the valves described above, it is particularly suited for manufacturing the integrally constructed valve shown in picture , and is described in connection with such a valve. the process may also be used to manufacture the pilot operated valve shown in picture

mold is provided with several parts investment casting, forward of an investment medium such as wax. several valve castingof such investment castings are in the shape of the pilot ports in the ends of valve body.

to manufacture valve by the investment casting process, the resilient material forming the valve is poured into mold , as shown in picture, and allowed to assume the resilient state. mold s then removed and the investment casting liquified and drained from valve body by heat, chemical, or other means, as shown in picture.