OLYM METALAbout OLYMWhy customers choose us?About us

-

Rich Experience

Serving global customers

01 -

ISO&TS16949

certificate of quality system

02 -

Competitive Price

Leading technology core

03 -

Value-added Service

Professional/ Dedicated

04 -

Fast Response

7*24 hours

05

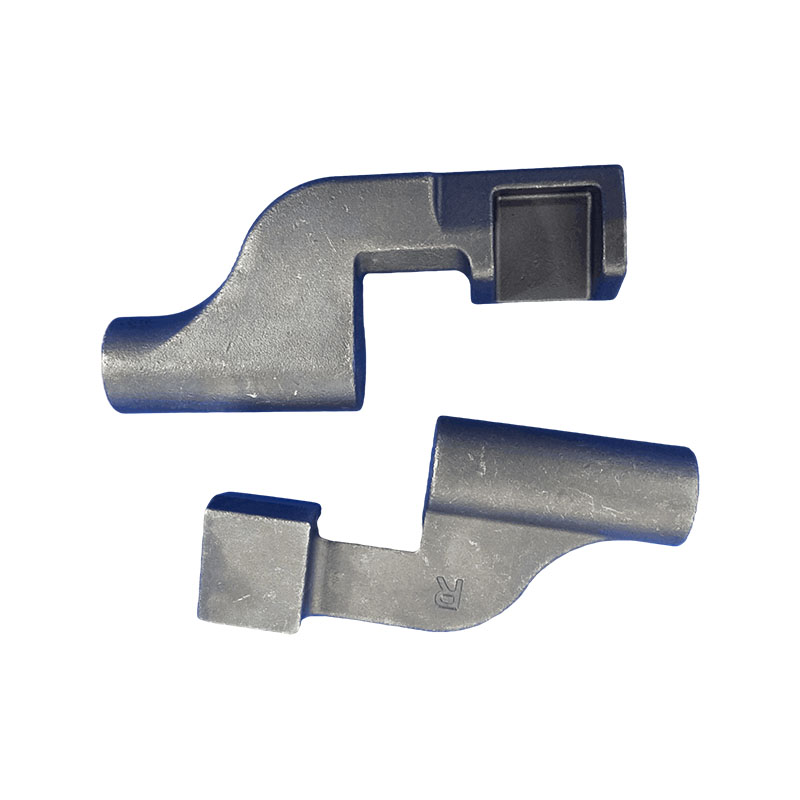

OLYM Metal Product Co.,LTD

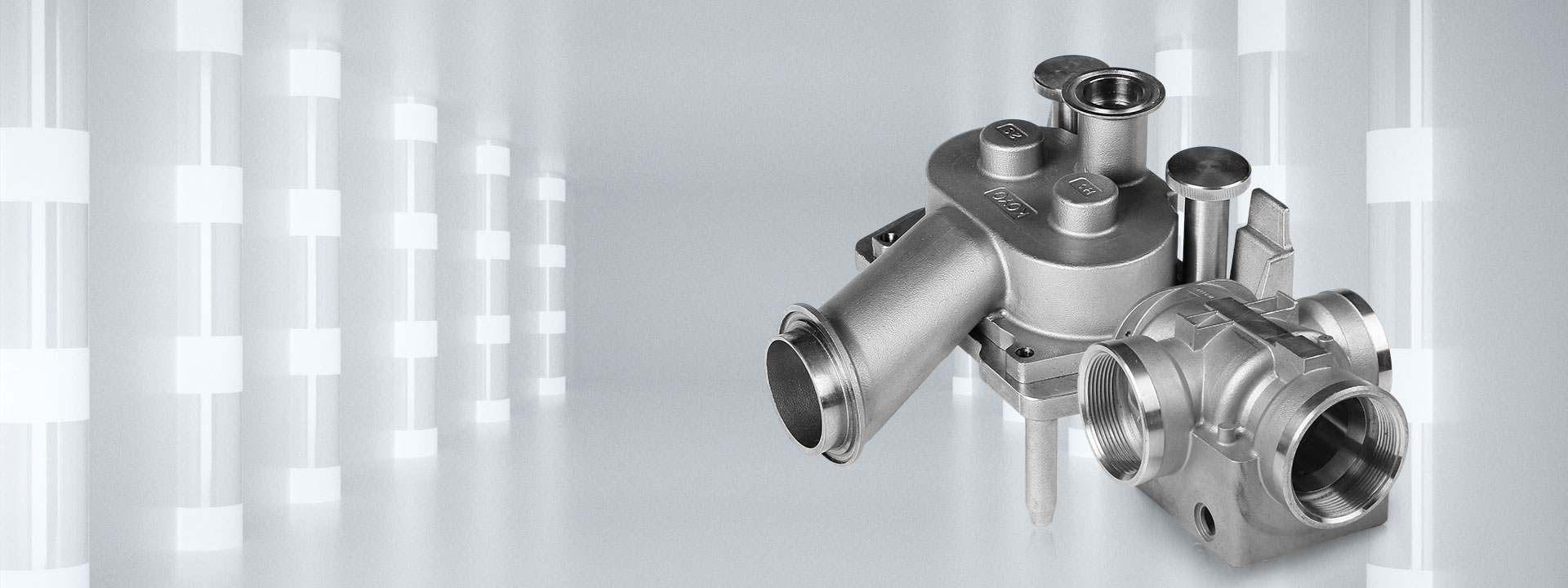

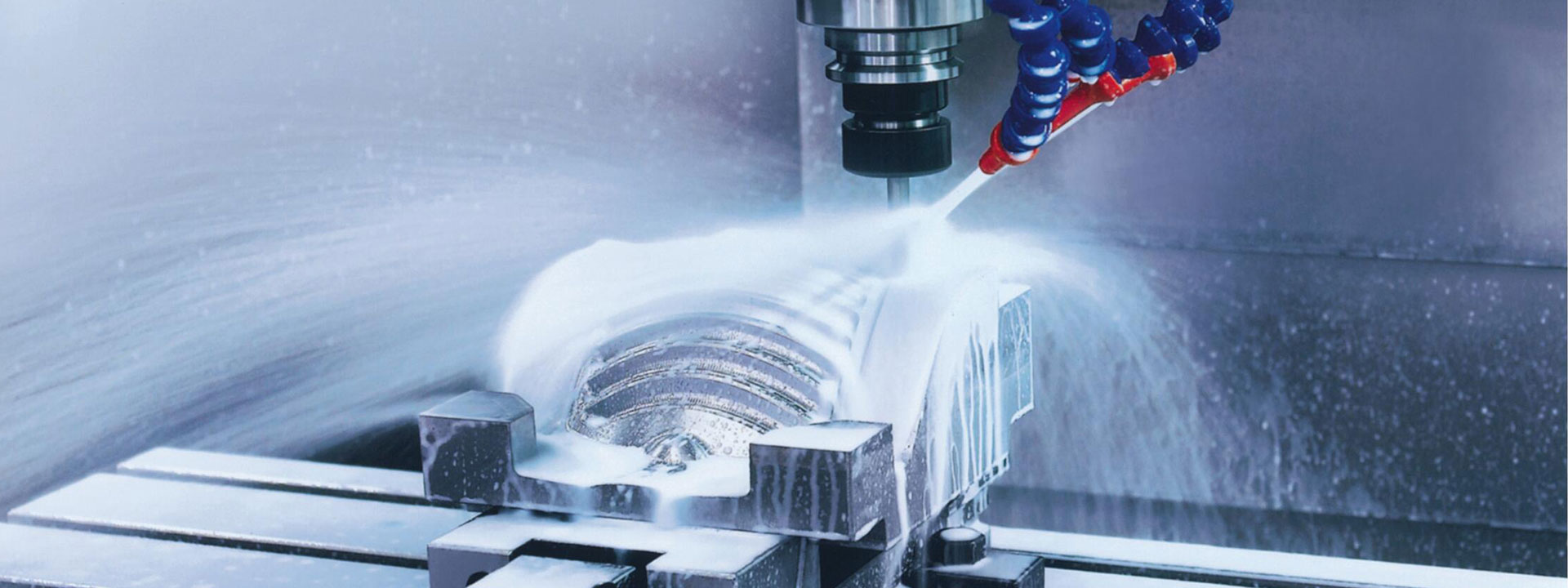

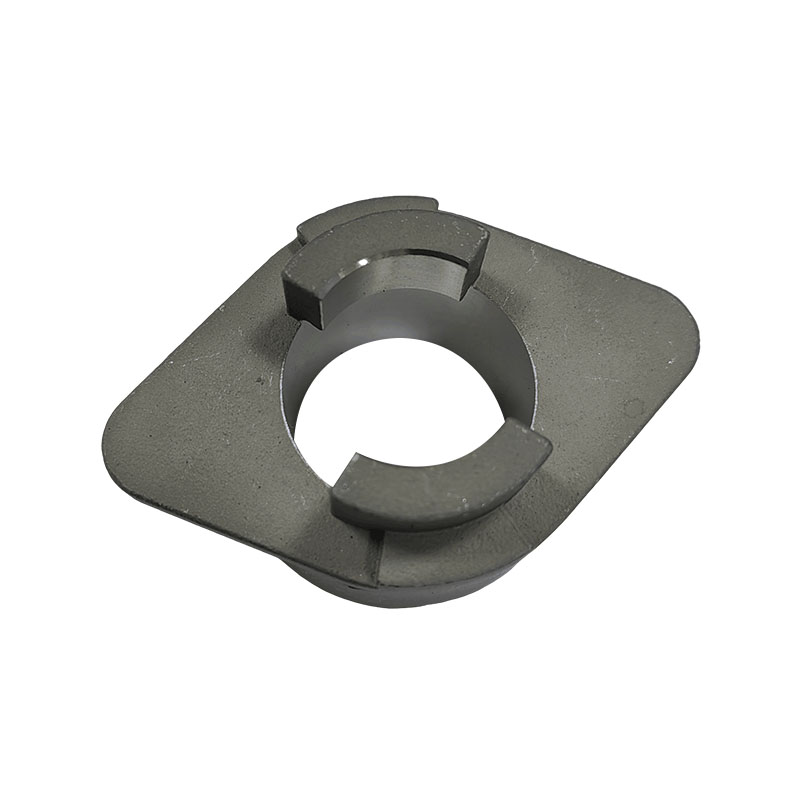

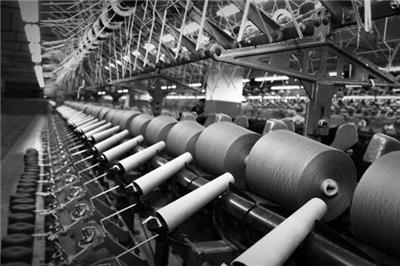

Professional / Trustworthy /2001 OLYM Metal Product Co,Ltd,which founded in 2001,is a high-tech private company ,the member of China Foundry Association, one of the top strong foundry in casting industry. And in the sports industry we are the only protective mask supplier designated by Rawlings. OLYM adopts advanced all silicon sol investment casting technology, produce all kinds of Ferrous casting,such as stainless steel casting,carbon steel casting ,alloy steel casting (alloy steel casting ,tool steel casting , wear-resistant alloy steel parts ,heat-resistant alloy steel investment casting parts),and other metal casting , mainly include automotive castings , mechanical components ,vehicle casting parts, marine hardware,valve casting ,pump casting and other precision engineered components, with an annual production ...Read more

OLYM METALNewsBased on management norms and guided by market demandnews

4/8/2024 12:00:00 AM

Quality with OLYM CASTING: Your Trusted Partner in Investment Casting

3/8/2024 3:37:27 PM

Why our investment casting factory called OLYM?

10/3/2023 6:09:22 PM

3D printing &Investment Casting For Bicycle Industry

9/1/2023 3:19:11 PM

Advancements in Automotive casting market with Silica Sol Investment Casting

7/20/2023 3:40:20 PM

Advancements in Medical Industry with Ferrous Metal Silica Sol Investment Castings

6/22/2023 4:50:11 PM

How Silica Sol Investment Casting Delivers High-Quality Precision Components?

5/18/2023 3:05:18 PM

Silica sol investment casting application in automotive parts and components

4/18/2023 5:23:54 PM